From conception to completion

StairCrafters Inc. offers a full range of services.

We work with the Architect, contractor, and homeowners to help create a staircase that’s not only a beautiful centerpiece but also a solid structure built with the finest craftsmanship.

We pride ourselves on our ability to fabricate staircases from wood, wrought iron, stainless steel, glass, and cable systems making us one of the most diversified stair companies in the country.

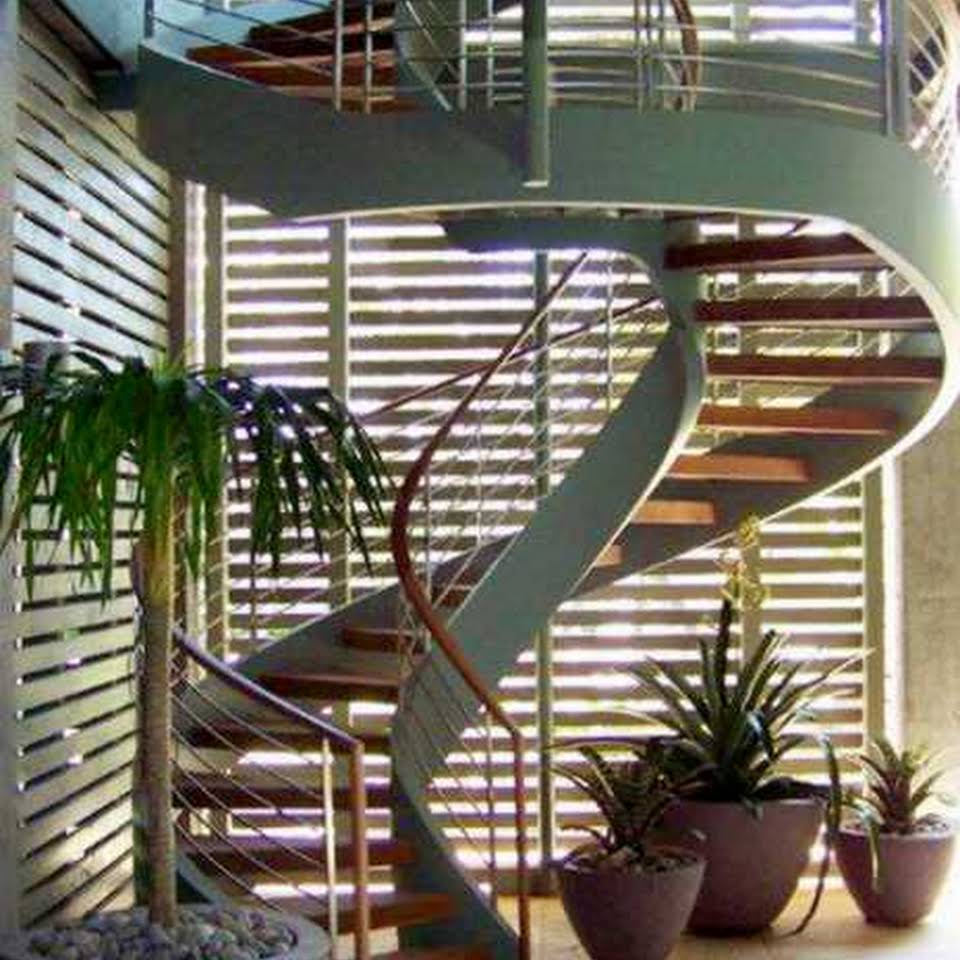

Curved Stairs

Stair Manufacturer/ Contractor

Spiral Stairs

Our Services

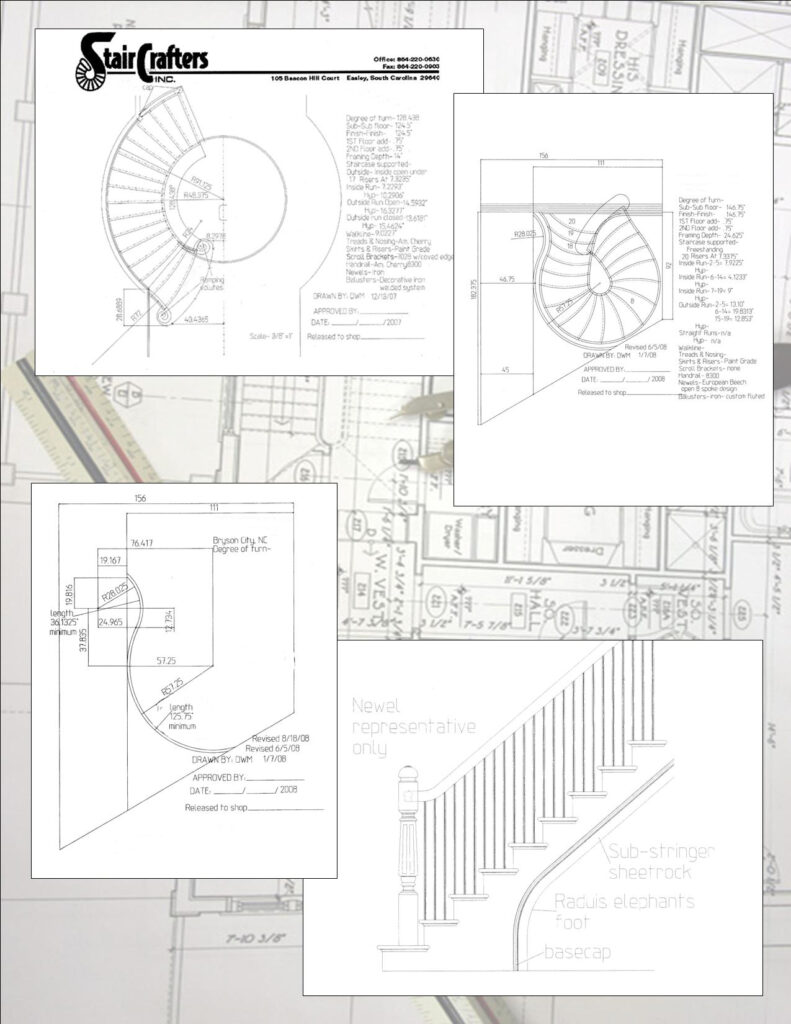

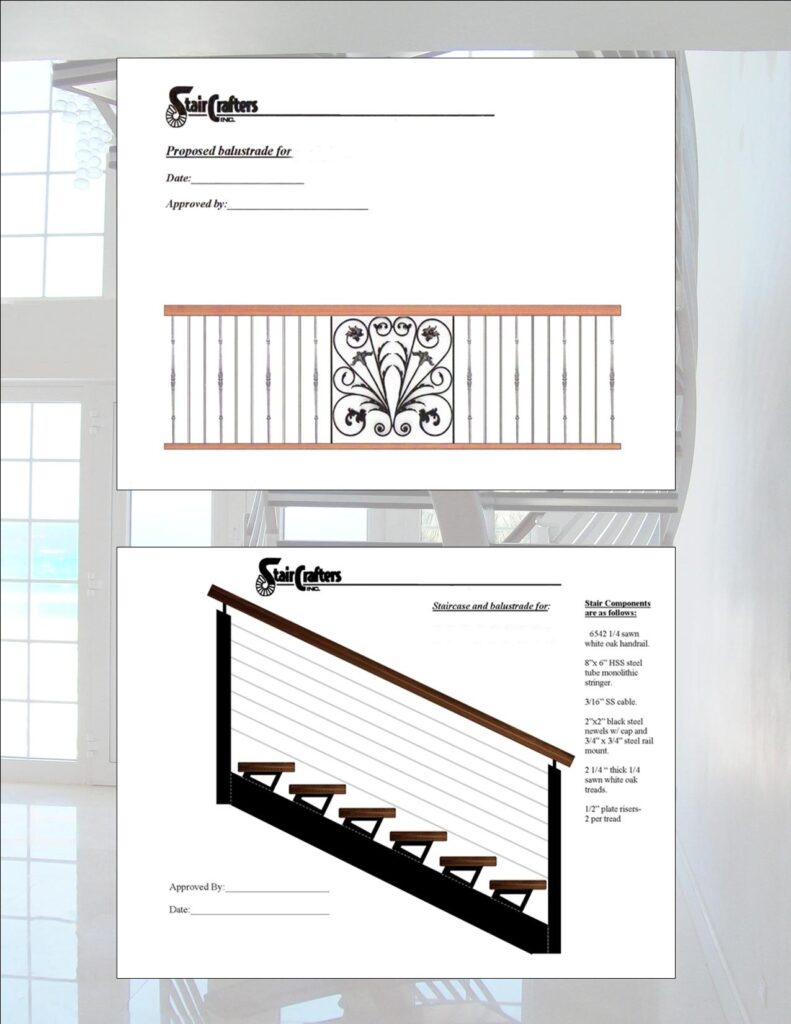

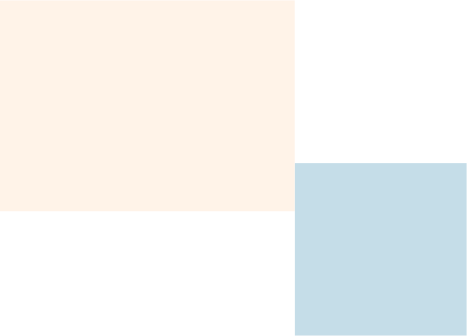

CAD Drawings

CAD (Computer-Aided Design) drawing is a powerful tool that can be used in the process of designing and constructing stairs. With CAD software, designers and engineers can create detailed, accurate drawings of stairs that can be used to guide the construction process.

Some of the benefits of using CAD drawing for stairs include:

Precise measurements: CAD software allows designers to create detailed, accurate drawings with precise measurements, ensuring that each component of the staircase fits together perfectly.

Visualization: CAD software can generate 3D models and visualizations of the staircase, allowing designers to see how the staircase will look in real life and make any necessary adjustments before construction begins.

Efficiency: With CAD software, designers can make changes to the staircase design quickly and easily, without having to redraw the entire plan.

Collaboration: CAD drawings can be easily shared and edited by multiple team members, allowing for greater collaboration and communication throughout the design and construction process.

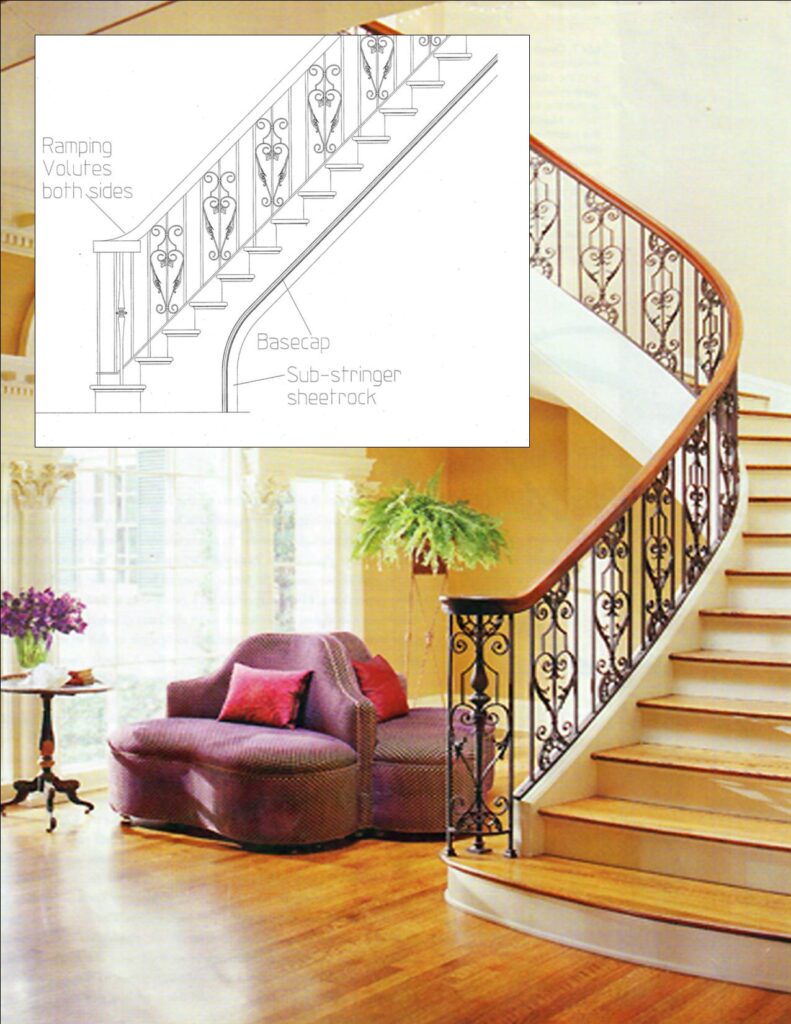

Renderings

Rendering is a process that takes a CAD drawing and creates a photorealistic image or animation of the object being designed. In the context of staircase design, rendering can be used to create highly detailed images or animations of the staircase design, allowing designers and clients to see how the final product will look in real life.

During the rendering process, specialized software uses complex algorithms to calculate the way that light will interact with the materials and surfaces of the staircase. This creates highly realistic shadows, reflections, and other visual effects that help bring the staircase design to life.

Rendering can be done in real-time or as a pre-rendered image or animation. Real-time rendering is typically used during the design process to allow designers and clients to see the design in real-time as changes are made. Pre-rendered images or animations are typically used for marketing materials, presentations, or other uses where a highly detailed and polished visualization is required.

Overall, rendering is a powerful tool that allows designers to create highly realistic visualizations of their designs, helping them to better communicate their ideas and designs to clients and stakeholders.

Fabracation

The fabrication process typically involves several steps:

Material selection: The first step in the fabrication process is selecting the appropriate materials for the staircase design. This may involve choosing different types of wood, metal, glass, or stone, depending on the design specifications and requirements.

Cutting and shaping: Once the materials have been selected, they are cut and shaped to the required size and shape using specialized tools like saws, drills, and lathes. This may involve cutting the materials to precise dimensions or shaping them into complex curves or angles.

Joining: Once the materials have been cut and shaped, they are joined together using a variety of techniques like welding, bolting, or gluing. This may involve joining metal components together or attaching wooden treads to metal or glass balustrades.

Finishing: Once the staircase has been assembled, it is finished using a variety of techniques like sanding, painting, or staining. This helps to protect the staircase from damage and gives it a polished, finished appearance.

Installation

Installation is the final step in the process of building a staircase. It involves taking the finished staircase and securely attaching it to the building structure, ensuring that it is level, stable, and safe to use.

The installation process typically involves several steps:

Site preparation: Before the staircase can be installed, the site must be prepared. This may involve removing any existing staircase, clearing debris, and preparing the area for installation.

Staircase placement: Once the site has been prepared, the staircase is carefully placed in position, ensuring that it is level and aligned with the building structure.

Attachment: The staircase is then securely attached to the building structure using specialized hardware like bolts, screws, or brackets. This ensures that the staircase is stable and safe to use.

Finishing touches: Once the staircase has been installed, any finishing touches like handrails or balustrades are attached. These not only enhance the staircase’s appearance but also provide additional safety and support for users.

Featured Projects

Hear From Our Clients

Can We Help?

Contact Us Directly For More Information Or Leave A Message Below And We'll Get Back To You ASAP

Phone

Opening Hours

Monday – Thursday: 7:30am – 4:30pm

Friday : 7:30am – 12pm

Saturday – Sunday : Closed